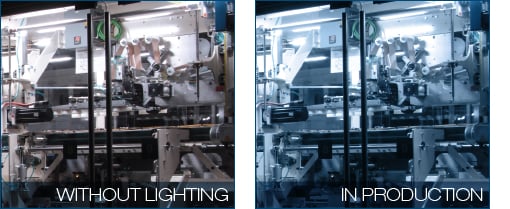

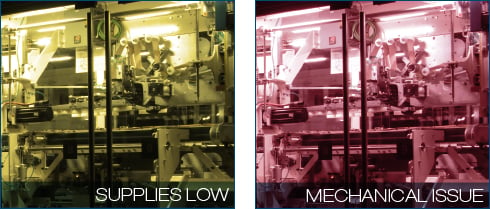

While others rely on HMIs and stack lights to alert operators to machine condition, Intelligent Illumination™ proactively cues operators where attention is needed. With task-based lighting, Intelligent Illumination™ allows clear visibility to issues without consulting the HMI.

LEDs Cast A New Light on Packaging Problem Solving and Productivity »

With more than 50 years of industry problem solving in end-of-line automation, Schneider Packaging Equipment Company, Inc. is a leading manufacturer of case packing and robotic palletizing solutions. Headquartered in Upstate New York, we design state-of-the-art machinery for customers in industries such as food and beverage, dairy, pharmaceutical, personal care, plastics, and paper.

© 2021 Schneider Packaging Equipment Company, Inc. | Privacy Policy